It goes without saying that this characteristic is incorporated in the development of your custom-made tube bending machine. This must be taken into consideration when producing the bending tool for the tube bending machine. Moreover, the so-called “springback” occurring after the bending process is completed is another factor that can only be compensated by overbending the workpiece. Due to the improved adjustability of the forces, a tube bending machine achieves the most precise bending results, even if thin-walled tubes made of titanium, aluminum, copper or stainless steels such as No.

This guarantees that our machines optimize your tube-bending requirements.įor example, if equipped with a vertically height-adjustable pressure die assembly, the bending forces are exerted precisely onto the thin-walled tubes. For this particular tube bending processes we have enhanced the transport boost of our tube bending machine and adjusted the bending tools accordingly. g., 60 x 1 mm, these special tubes may measure only 60 x 0.6 mm. While conventional tubes may have a wall thickness of, e. Thin-walled tubes are usually made of very susceptible materials such as aluminum and titanium and, during the forming process, they are extremely demanding and prone to cracking. Simultaneously, this pressure die stabilizes the straight end of the pipe during the bending process. For example, shear forces that are generated during the bending process can be absorbed by a pressure die.

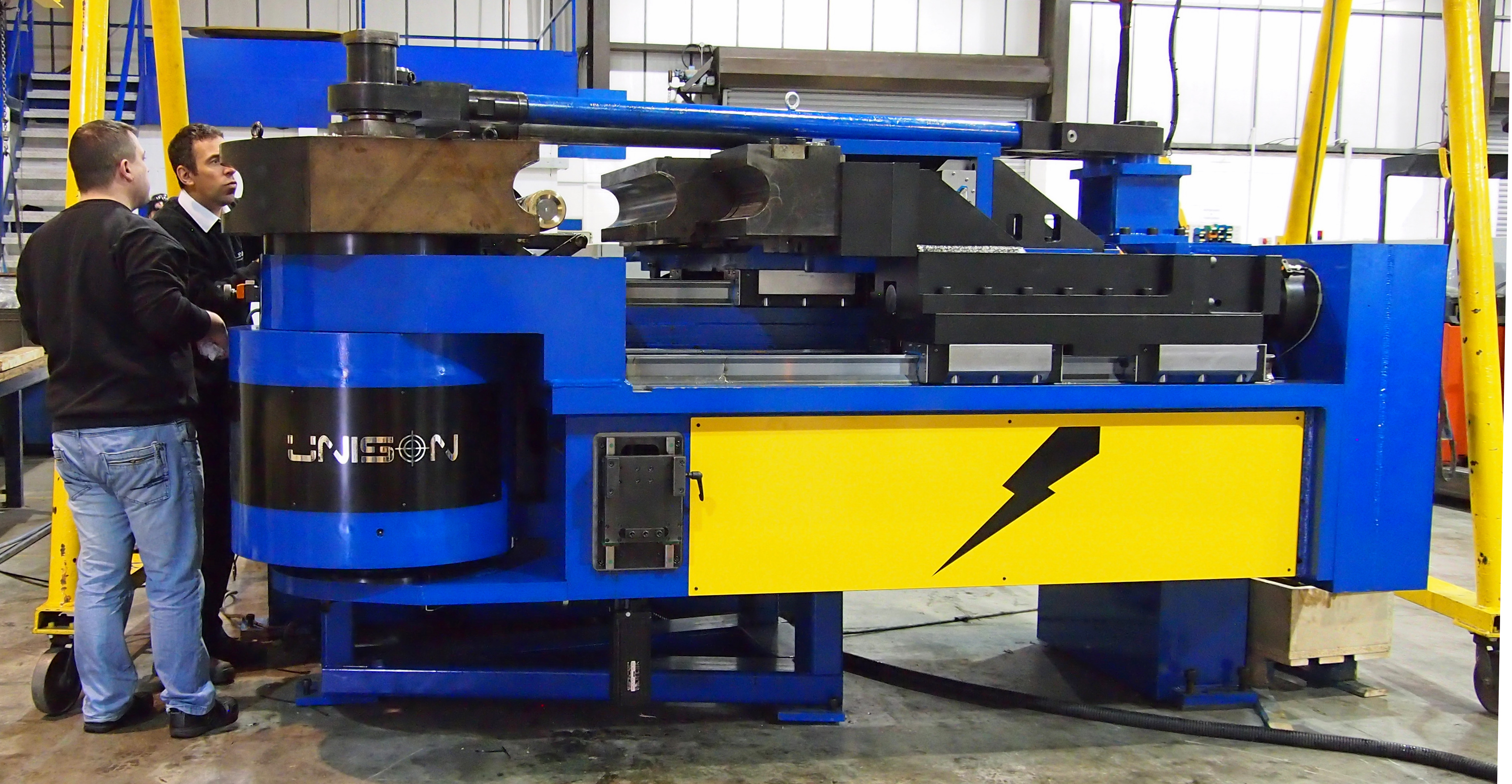

These factors, in addition to the material and its properties, require special attention. When using the cold-bending method, many factors such as tension, elongation, yield points, tensile forces, and shear forces do occur. Operating principle of a tube bending machine Our tube bending machines are available in a variety of designs:įurthermore, a large selection of optional extras is also available – optimized to suit your specifications.

Tube bending machine iso#

In 2003, we took the initiative to bring ourselves in line with ISO standard 9001. Our Quality Management is confirmed by TÜV Rheinland (a global provider of technical, safety, and certification services in Germany) and ISO-certified at regular intervals. Needless to say, each tube processing machine manufactured in-house meets the highest quality requirements regarding design and workmanship.

Tube Bending Machinesfor tube diameters from 4 to 420 mm.Our range of products includes, among other things: Virtually in every industry branch, in which a tube bending machine is utilized, our machines can be employed. Our range of tube bending products comprises machines and systems for a variety of application areas. As one of the world's leading companies in the manufacture and development of bending machines, we offer you custom-made solutions for your individual tube bending machine.

0 kommentar(er)

0 kommentar(er)